Custom-made catalyst leads to longer-lasting and more sustainable green hydrogen production

phys.org

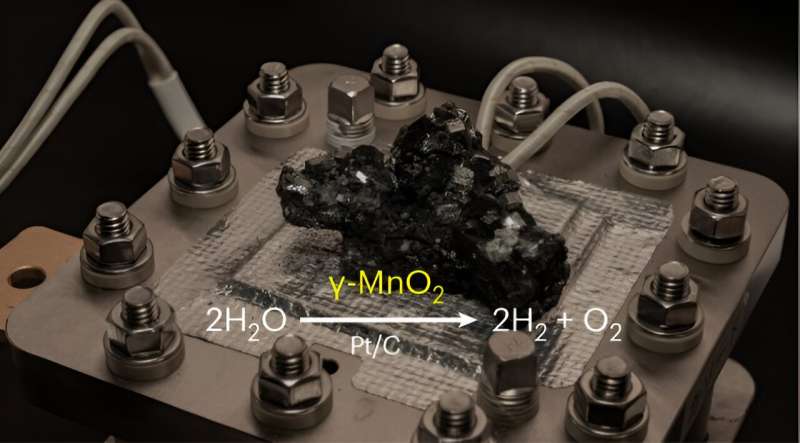

Researchers led by Ryuhei Nakamura at the RIKEN Center for Sustainable Resource Science (CSRS) in Japan have improved on their green and sustainable method of extracting hydrogen from water by using a custom-made catalyst for the chemical reaction.

Published in Nature Catalysis, the study details how they manipulated the catalyst's 3D structure, which led to improved stability and an increase in the catalyst's lifetime by almost 4000%. The findings impact the ability to achieve a lasting and sustainable hydrogen-based energy economy.

Water electrolysis using proton exchange membranes is a green electrochemical process for splitting water into oxygen and hydrogen. Hydrogen produced this way can then be stored and used at a later time.

For example, when combined with a proton exchange membrane (PEM) fuel cell, the stored hydrogen can be used to power an electric car. However ...

Copyright of this story solely belongs to phys.org . To see the full text click HERE