Raspberry Pi cuts product returns by 50% by changing up its pin soldering

arstechnica.com

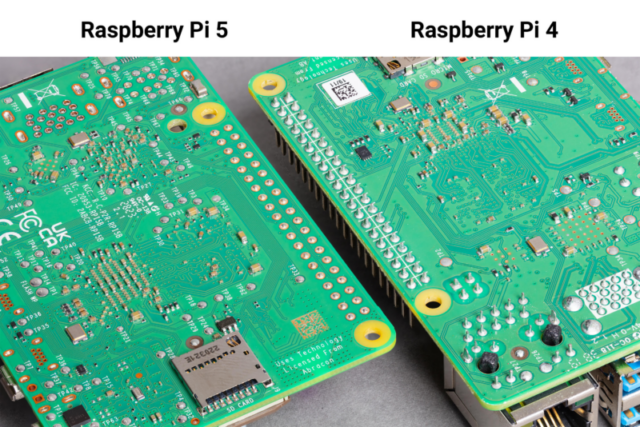

Comparison of undersides of Raspberry Pi 5 (left) and Raspberry Pi 4. Note the smaller pin presence on the Pi 5, potentially reducing the board's exposure to physical defects and damage to connectivity. Credit: Raspberry Pi

Getting the hang of through-hole soldering is tricky for those of us tinkering at home with our irons, spools, flux, and, sometimes, braids. It's almost reassuring, then, to learn that through-hole soldering was also a pain for a firm that has made more than 60 million products with it.

Raspberry Pi boards have a combination of surface-mount devices (SMDs) and through-hole bits. SMDs allow for far more tiny chips, resistors, and other bits to be attached to boards by their tiny pins, flat contacts, solder balls, or other connections. For those things that are bigger, or subject to rough forces like clumsy human hands, through-hole soldering is still required, with leads poked ...

Copyright of this story solely belongs to arstechnica.com . To see the full text click HERE